|

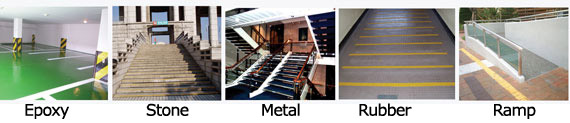

| Leading-edge antislip treatment "COATING SLIP-STOP HARD" for vehicles and pedestrians |

|

|

Feature Feature |

|

| Applicable to all kinds of floorings like plastic, rubber, glass, metal, wood, tile, stone, etc. |

|

| Excellent antislip effect with rough irregular surface profiles of strong metal components. |

|

| Long lasting for vehicles and pedestrians. |

|

| High chemical resistance and many colors available. |

|

| Cost saving thru long duration time. As there is no odor and growth of microorganism, clean floor can be maintained. |

|

|

|

|

| [Comparative Tables - “COATING SLIP-STOP HARD”and “Slip-protection tape”] |

|

|

|

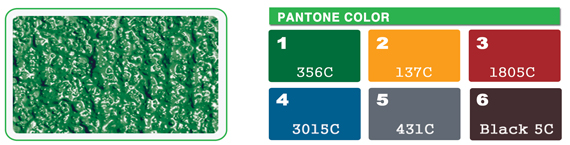

Applicable Material of Floor Applicable Material of Floor |

| | All kinds like epoxy, glass, metal, rubber, wood, plastic, stone, etc. |

|  |

|

|

Typical Application Typical Application |

| | parking space, gas station, factory, entrance, highway rest area, school, building, apartment, hotel, motel, mart, shopping center, health club, hospital, asylum, kindergarten, swimming pool, air port, vessel, etc. |

|  |

|

|

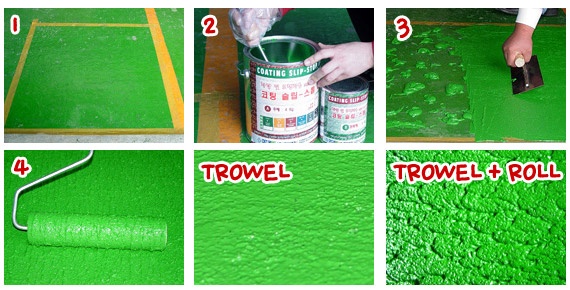

Application Method Application Method |

|

| 1. | Clean out the floor thoroughly with clean water and detergents and make it dry. |

| 2. | Tape the boundary lines. |

| 3. | If the floor is rough or porous surface like concrete, cement etc., apply epoxy primer and dry it for strong adhesion. |

| 4. | Stir the base material A well with a strong stick. |

| 5. | Stir hardener B with another stick. |

| 6. | Mix the base material A and hardener B well. |

| 7. | Divide and put the mixed product on the floor evenly and spread out well with plaster's trowel. |

| 8. | If normal rough profile of antislip surface is required, finish the work with only trowel. After removing tapes, use the floor after complete dried. |

| 9. | If higher rough irregular profile of antislip surface is required, spread with designated hard roller after the job of plaster's trowel, the above. For the ramps, the direction of rolling is recommended to be across with the direction of vehicles or people. After removing tapes, use the floor after complete dried. |

|

|

|

|

|

Caution Caution |

|

| 1. | The coating jobs should be finished within 20 minutes from mixing to completing the work. If failed, product can not be used because of hardened. |

| | | ※ | If you apply more than one can, you should prepare the mixing and do coating job one by one following the same repeated procedures. |

|

| 2. | While drying, keep it dry. Avoid snow, rain and water. |

|

|

|

Reference Reference |

|

| Dry time | normally 8~48 hours

Spring: about 12hours(15℃~25℃)

Summer: about 8hours (25℃~35℃)

Fall 12hours(15℃~25℃)

Winter 24~48hours(0℃~15℃) |

| Usable time | about 20 minutes(Please spread as possible as fast within 20 minutes after mixing) |

| Roller | Do not use other rollers except for designated one since it does not rolled well and also doesn't make unevenness. |

|

|

|

|

|

|

|

| Cases |

|

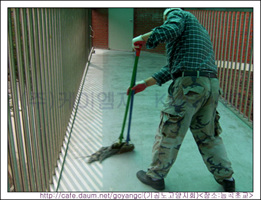

| Preparation |

Taping |

|

|

| |

|

Mixing Base Material and Hardener

|

Spreading with Trowel |

|

|

| |

|

Rolling |

After Removing tapes 1 |

|

|

| |

|

| Picture 2 |

Picture 3 |

|

|

| |

|

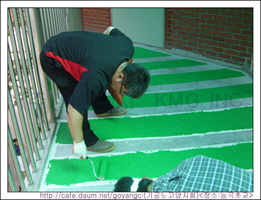

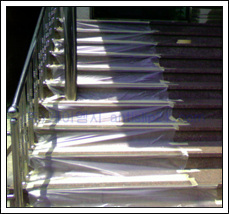

Preperation for Applying at Marble Stairs

|

After Applying |

|

|

| |

|

Applied on Metal Stairs

|

Applied on Tile Ramp |

|

|

| |

|

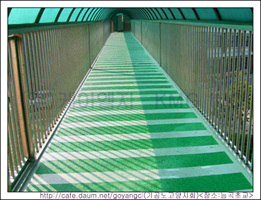

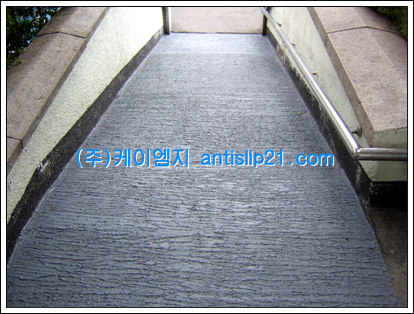

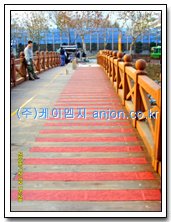

Ramp1

|

Ramp2 |

|

|

| |

|

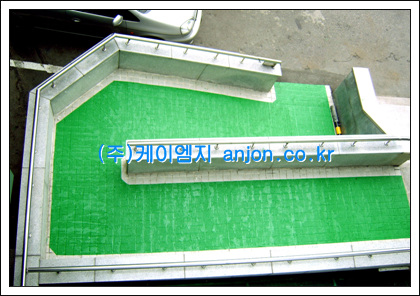

Ramp3

|

Parking Lot |

|

|

| |

|

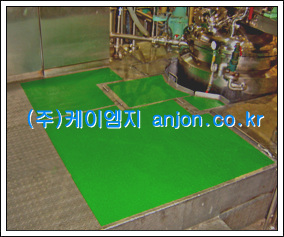

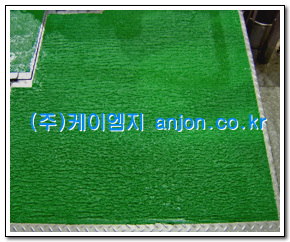

Metal Floor of a Factory 1

|

Metal Floor of a Factory 2 |

|

|

| |

|

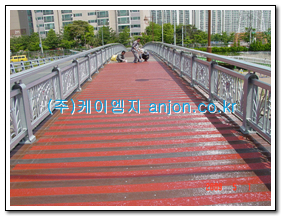

Wooden Bridge 1

|

Wooden Bridge 2 |

|

|

| |

|

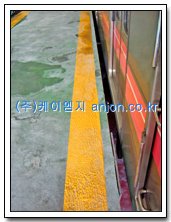

Seoul Subway

|

Fishery Market 1 |

|

|

| |

|

Fishery Market2

|

Fishery Market3 |

|

|

| |

|

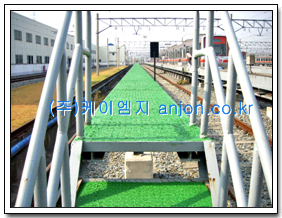

Deagu Subway1

|

Deagu Subway2 |

|

|

| |

|

Pakring Lot 1

|

Parking Lot 2 |

|

|

| |

|

Parking Lot 3

|

Parking Lot |

|

|

| |

|

Wooden Bridge

|

|

|

|

|

| |

|

|

|

| Cautions | |

| |

| - Keep it cool and ventilated places. |

| - DO NOT eat or inhale, and immediately wipe out when it is contacted on skin. |

|

|

| Req. Application |

|

| Please contact us if you have questions for application through e-mail, telephone, or homepage (TEL: 82-41-554-5064) |

|

|

|

|

|

|

|